Flame Spray Thermal Coatings for Industrial Corrosion Protection & Restoration

Tennessee Metallizing offers you expert flame spray services on-site or in-shop depending on your needs. Appropriate for any number of industrial, commercial and artistic applications, flame spray is another thermal spray process where a hard protective coating is applied to the prepared surface to provide protection from wear and erosion, restoration of worn parts and corrosion protection. Expensive parts often wear out prematurely from constant use. A flame spray coating produces a stronger, more durable surface that is up to 10x harder than the base metal. It thereby increases the overall life of your part by up to 50%, providing you with on-going cost savings for the long run. Because the process is fast and portable, utilizing gas instead of electricity, we are able to reduce your downtime significantly by performing the work at your location no matter where it might be – in your plant, at your construction site – virtually anywhere.

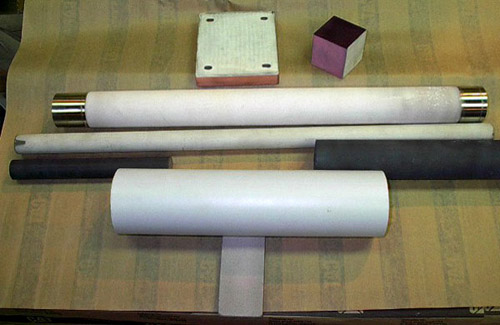

Flame spray coatings are typically ceramic coatings, metal alloys, and spray-and-fuse coatings. Spray and fuse coatings create a metallurgical bond to the base metal, with some carbide spray-and-fuse coatings producing hardness ranges up to Rockwell 88C. Resulting in less porous finishes, these coatings are able to resist abrasive grains, particle erosion, sliding erosion, fretting or wear, cavitation, and harsh environments caused by climate or chemicals. Tennessee Metallizing utilizes an oxyfuel torch to apply the coatings. You may also be interested in metallizing, another of our thermal coatings processes, or powder coatings. You can contact us using our convenient online form.

Tennessee Metallizing offers you expert knowledge and skill to ensure you fast, professional, courteous service and a solution that makes sense for you. Our flame spray service has many applications for OEMs, architects, design engineers, physical engineers, plant managers, government, aerospace, aeronautical, marine, highway & safety, military and defense, forestry, and construction, to name a few. It works well on metal parts and some non-metal surfaces.

What our metallizing service offers you:

- Corrosion protection

- Portable Process

- Restore worn out parts

- Fast Process – Reduces production downtime

- Greater durability

- Same day service

- Stronger surface up to 10x harder than base metal

- No waiting for overseas part to arrive

- Extended life – Up to 50% longer

- On-site or in-shop service

- More cost effective than replacing parts

- Expert, Professional, Courteous service

Tennessee Metallizing looks forward to the opportunity to be your single source provider for corrosion protection and restorative services for your metal parts, equipment, machinery, structures and surfaces.

Tennessee Metallizing – Industrial Corrosion Protection & Thermal Coatings